PTO Overview Specifications & History

CCA Website Editor’s Note:

This article was obtained from the radiomuseum.org website from the following url: http://www.radiomuseum.org/forum/design_excellence_the_collins_pto.html

Emilios Ciardiello’s contribution was well done and we would like to also present it here in our PTO section since it presents a very good overview of the work done by Collins on their various PTOs over this time period.

There is a very good set of data on the various PTOs and their specifications as well as a cross reference to the Collins Part Number (CPN)

A Perspective on the Development and Manufacturing Run of the Collins PTO

by Emilio Ciardiello

Around the end of WWII, in the golden age of analog designs, Collins set new standards for tuning accuracy and stability in communication equipment, culminated since the early ‘950s in the introduction of digital mechanic readout sets, as the R-390. Specs of these sets were simply exceptional, with overall accuracy and stability figures unsurpassed until the introduction of digital frequency synthesizers. A relevant role was played by the Permeability Tuned Oscillator or PTO used as variable tuning local oscillator. The first known use of a PTO as a replaceable subassembly could be dated around 1945 with the RT-91/ARC-2 transceiver. Some details evolved in the years, as the tuning range and the turns of the tuning shaft, the use of miniaturized components and of subminiature tubes or even semiconductors, or the use of a temperature controlled oven for models to be operated in extreme environmental conditions. Nevertheless the basic design remained unchanged for about a quarter of a century.

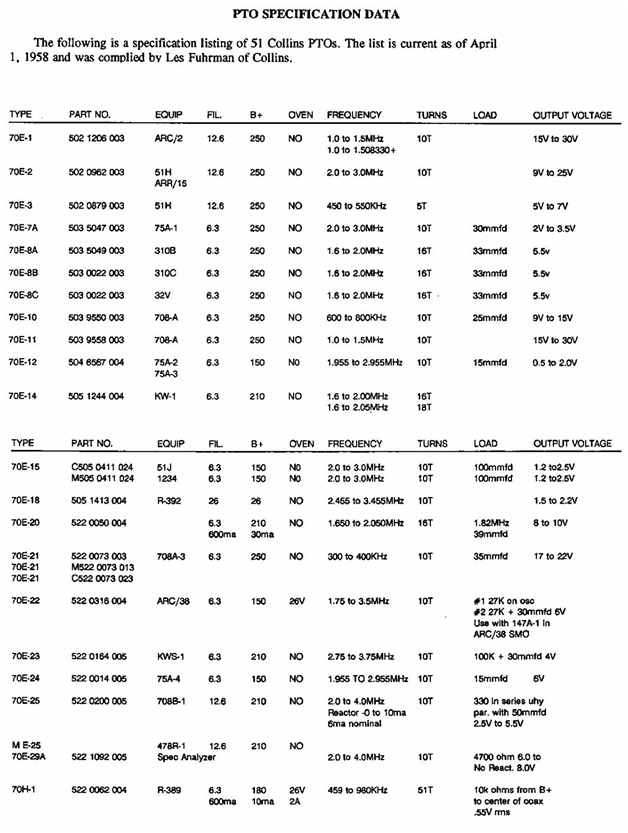

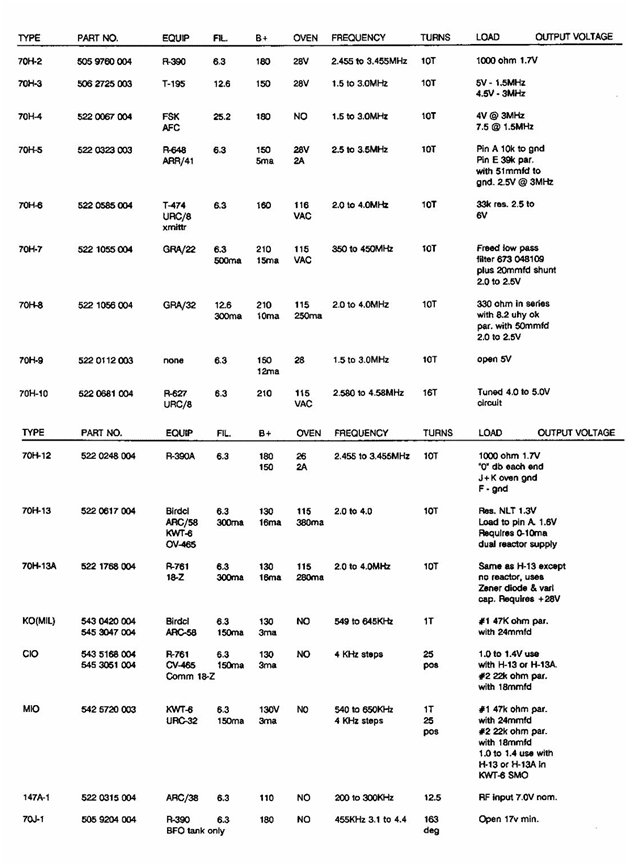

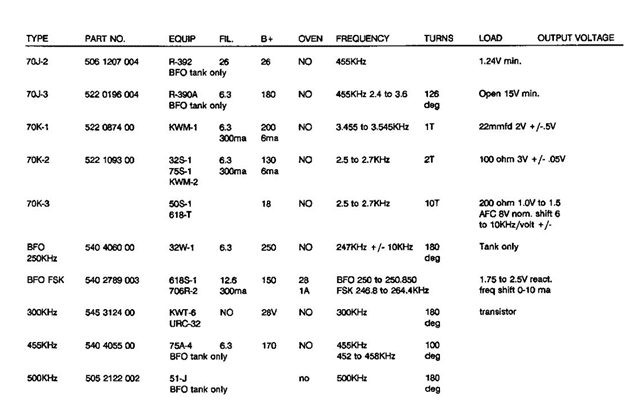

Collins permeability tuned oscillators are listed in the table below.

Figures 1-3 Lists of Permeability Tuned Oscillators as of 1958 (source Collins Radio)

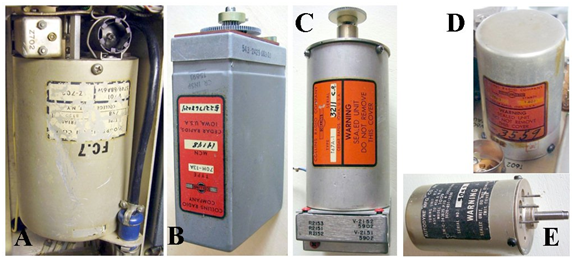

Here is a little survey of permeability tuned oscillators, most from Collins, a couple from some of the several second sources grown for the military market.

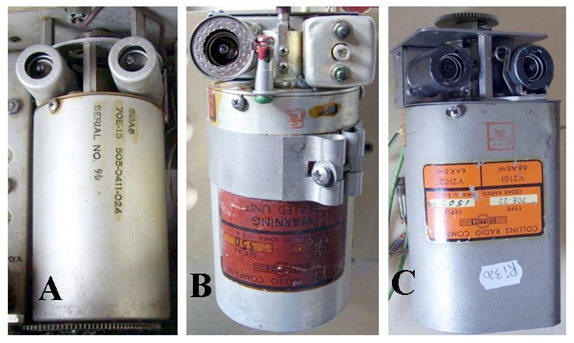

• 1A, the 70E-15 PTO is used in the 51J line; 2.0 to 3.0MHz over 10 shaft turns.

• 1B, the 70E18 is the variable oscillator of the R-392 vehicular receiver; 2.455 to 3.455MHz over 10 turns, 26VDC heater and B+ supply.

• 1C, this is a thermostatic 70E-22 PTO used in the RT-311/ARC-38 airborne transceiver; 1.75 to 3.5MHz over 10 turns.

• 2A, the 798 from Progressitron is an appreciated replacement for the Collins 70H-2, the thermostatic PTO used in the R-390/R-390A military receivers; 2.455 to 3.455MHz over 10 turns.

• 2B, the 70H-13 was used in ARC-58 airborne radio set; subminiature tubes, 2.0 to 4.0MHz over 10 turns.

• 2C, the 147A-1 is also used in RT-311/ARC-38; tunes from 200 to 300KHz over 12.5 turns of the shaft.

• 2D, the 70J-2 is the BFO tuning coil used in the R-392 and retains the same hermetic execution and ruggedness of other permeability tuned oscillators.

• 2E, this is an Autodyne 1009, alternate part for the Collins 70J-3 used in the BFO of the R-390A; tunes from 452 to 458KHz.

To give an idea of the exceptional performances reached we can give a look at the specs of the PTO used in the R-390, the 70H-2. The tuning range covers exactly 1MHz, from 3455 to 2455KHz, in exactly 10 turns of the shaft. The non-linearity error is lower than 300Hz. The PTO thermal drift does not exceed 500Hz from –40 to +60 deg. C and its direction has been calculated to compensate drifts of the remaining circuits, so to grant an overall stability of the receiver better than 300Hz from –40 to +65 deg. C. From the figures above, in the R-390 the PTO is about as stable and accurate as the crystal oscillators. Slightly worse figures can be found in the case of a PTO without thermostatic oven, such as the 70E-15 used in the 51J line. Here the overall maximum error, also including errors of the two crystal oscillators, is not greater than 2KHz from –20 to +60 deg. C.

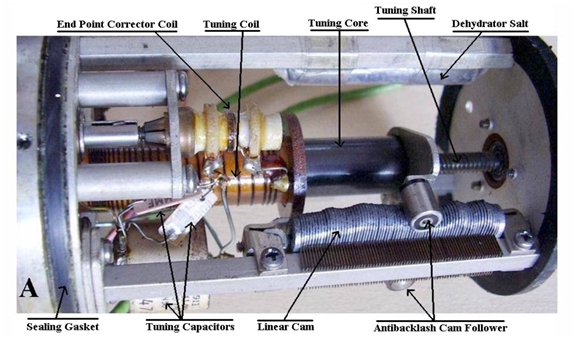

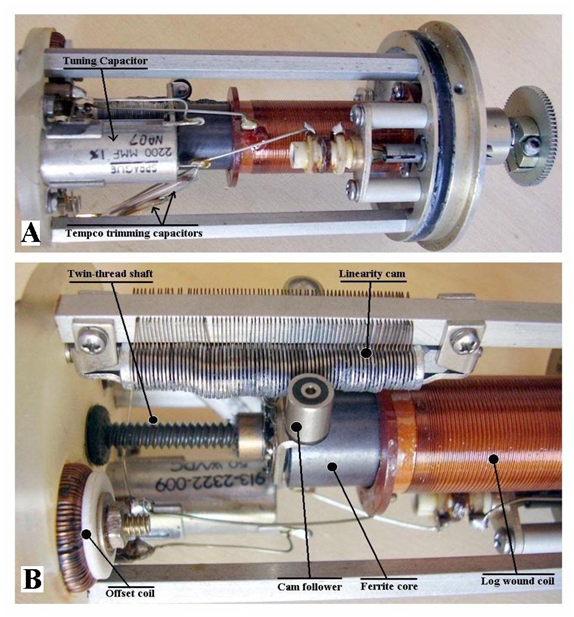

The secrets for the said results can be found in the extreme care of the design and of the engineering of the permeability tuned oscillators. The tuning components are hermetically enclosed in an aluminum can, just leaving outside the tube(s) and the related biasing and decoupling parts. Variable inductance tuning is used to prevent the microphonics usually associated with variable capacitors. The winding is logarithmic, to ensure a straight-line frequency tuning. The sintered powder core moves smoothly in and out of the coil, driven by a double-threaded tuning shaft and an anti-backlash female screw. To compensate for imperfections in the winding geometry, the advancing of the core is controlled by a factory adjusted cam profile and a spring-loaded cam follower, so making linear the frequency variation through the tuning range. The main tuning capacitor is a precision hermetically sealed ceramic unit, as the 1% tolerance types from Sprague-Herlec, selected for very low temperature coefficient. Small temperature controlled ceramic capacitors are added in parallel to the first one, to get the specified thermal drift. A small variable inductance is added in series to the main one to precisely adjust the frequency end-point. In some PTO models capsules containing dehydrating salt are added to adsorb moisture. Small O-rings seal the bushings of tuning shafts, both the main and the end-point adjusting ones. Figures 3 and 4 below show some details of the 70E-22 and of the 147A-1.

Fig. 3 – This is the internal view of the 70E-22 PTO, showing in the background the main tuning components, the logarithmic wound coil, the tuning core and the threaded shaft. In the foreground, the end-point adjusting coil, the cam, the cam follower and the tuning capacitors, the larger one partly covered by one of the square rods.

Fig. 4 – Two internal views of the 147A-1 PTO. 1A shows the main tuning capacitor, a 2200pF plus/minus 1% sealed unit, characterized for an extremely low temperature coefficient, a mere 7 ppm figure annotated on the body. 4B shows details of the variable tuning parts. The cam profile is formed by some 100 tiny adjustable segments; thin spacers among them allow the adjusting of each segment without disturbing the near ones. The toroid coil on the left is used to obtain a narrower tuning range.

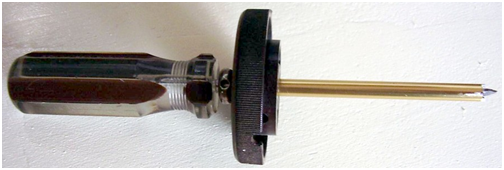

Very few details are given about the components and the calibrating procedures of these subassemblies, with some exceptions for the end-point corrector coils. Often (even for the adjustment of this coil) special tooling was require – including test cables, a graduated or better a multi-turn knob and sometimes a special screwdriver. Figure 5 shows the special home-made tool for adjusting the corrector coil of the 70E-15. Indeed these units were usually factory sealed while being held at high temperature and had to be returned to the manufacturer or to authorized centers for servicing the components inside the hermetic can.

Fig. 5 – The home-made coaxial screwdriver required for adjusting the end-point of the PTO used in the 51J receivers.

This article was edited 28.Nov.10 18:24 by Emilio Ciardiello .